The Airman

Andy went along to Music Hack Day, London. Here‘s the result of that weekend’s hacking.

The Airman

Generative audio from found 16mm film.

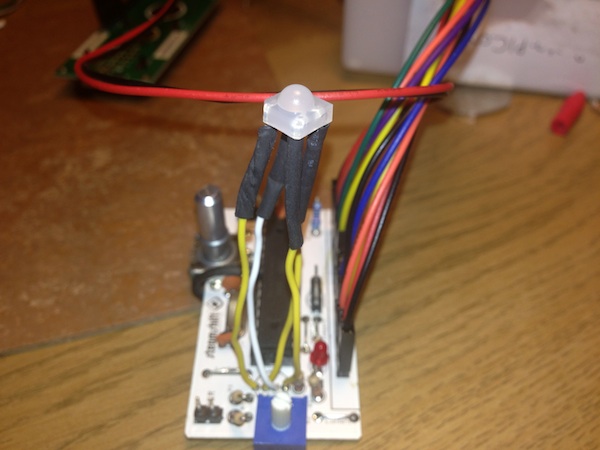

Projecting the found footage of “The Airman” using a scratch built film projector (created using a few parts from a defunct projector, 3d printed parts and threaded rod).

The film is projected onto a small screen and captured by a USB webcam feeding into Quartz Composer to process the footage and then capture pixel values, which are then passed by midi to Pure Data.

The PD sketch was created by Martin Brinkmann, and adapted to accept the passed midi controller values to adjust the sounds being created.

In future, I hope to get the film sync'd with a strobing light source, to produce a still image; and to construct a PD (or similar) sketch from scratch to generate the music.